Assembly Thermocouple

Product Application

Usually used in conjunction with display instruments, recording instruments, electronic computers and so on. Direct measurement of various production processes (0 ~ 1300)°C range of liquid, steam and gas media and solid surface temperature.

Product Principle

The electrodes of the Armored Thermocouple consist of two different conductor materials. When there is a temperature difference between the measuring end and the reference end, a thermoelectric potential is generated and the working instrument displays the temperature value corresponding to the thermoelectric potential.

Product Features

- Less thermal response time, reducing dynamic errors.

- Bendable mounting for use.

- Large measuring range.

- High mechanical strength, good pressure resistance.

- Junction box protection level IP65, IP66.

Technical Parameters

1. Executive Standard of the Product

- International standard IEC60584.

- National standard GB/T18404, GB/T304292.

2. Room Temperature Insulation Resistance

The insulation resistance of the Assembly Thermocouple is ≥ 1000 MΩ between the electrode and the outer casing at an ambient temperature of (20 ± 15)°C, a relative humidity of not more than 80%, and a test voltage of (500 ± 50)V DC. That is, the insulation resistance of a 1m-long specimen is 1000MN; and the insulation potential of a 10m-long specimen is 100 MΩ.

3. Temperature measurement range and tolerance

| s el | Graduation | Tolerance level | |||

|---|---|---|---|---|---|

| I | II | ||||

| Tolerance value | Temperature range | Tolerance value | Temperature measurement range | ||

| WRNK | K | -40 ~ +375 | ±1.5°C | -40 ~ +333 | ±2.5°C |

| 375 ~ 1000 | ±0.004|t| | 333 ~ 1200 | ±0.0075|t| | ||

| WRMK | N | -40 ~ +375 | ±1.5°C | -40 ~ +333 | ±2.5°C |

| 375 ~ 1000 | ±0.004|t| | 333 ~ 1200 | ±0.0075|t| | ||

| WREK | E | -40 ~ +375 | ±1.5°C | -40 ~ +333 | ±2.5°C |

| 375 ~ 800 | ±0.004|t| | 333 ~ 900 | ±0.0075|t| | ||

| WRFK | J | -40 ~ +375 | ±1.5°C | -40 ~ +333 | ±2.5°C |

| 375 ~ 750 | ±0.004|t| | 333 ~ 750 | ±0.0075|t| | ||

| WRCK | T | -40 ~ +125 | ±0.5°C | -40 ~ +133 | ±1.0°C |

| 125 ~ 350 | ±0.004|t| | 133 ~ 350 | ±0.0075|t| | ||

| WRPK | S | 0 ~ +1100 | ±1.0°C | 0 ~ 600 | ±1.5°C |

| 1100 ~ 1600 | ±[1+0.003(t-1100)] | 600 ~ 1600 | ±0.0025|t| | ||

| WRQK | R | 0 ~ +1100 | ±1.0°C | 0 ~ 600 | ±1.5°C |

| 1100 ~ 1600 | ±[1+0.003(t-1100)] | 600 ~ 1600 | ±0.0025|t| | ||

| WRRK | B | / | / | 600 ~ 1700 | ±0.0025|t| |

4. Thermal Response Time (t0.5)

| Protection tube diameter (mm) | Protective tube material | Thermal response time (s) |

|---|---|---|

| Ф16 | Non-metallic | ≤240 |

| Metallic | ≤180 | |

| Ф20 | Metallic | ≤240 |

| Ф25 | Non-metallic | ≤300 |

| Conical protective tube | Metallic |

Model Naming Method

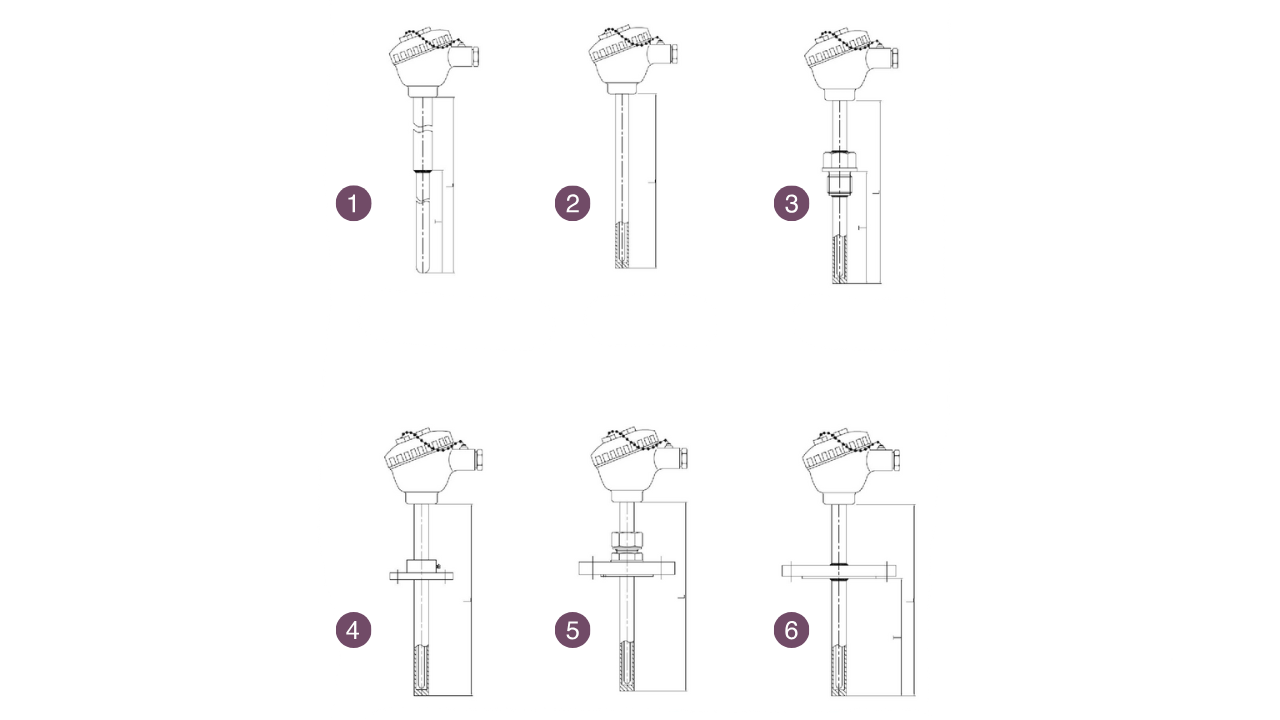

Structure diagram

- WRN-130 (Non-metallic protective tube)

- WRN-130

- WRN-230

- WRN-330

- WRN-330 (Adjustable ferrule flange)

- WRN-430

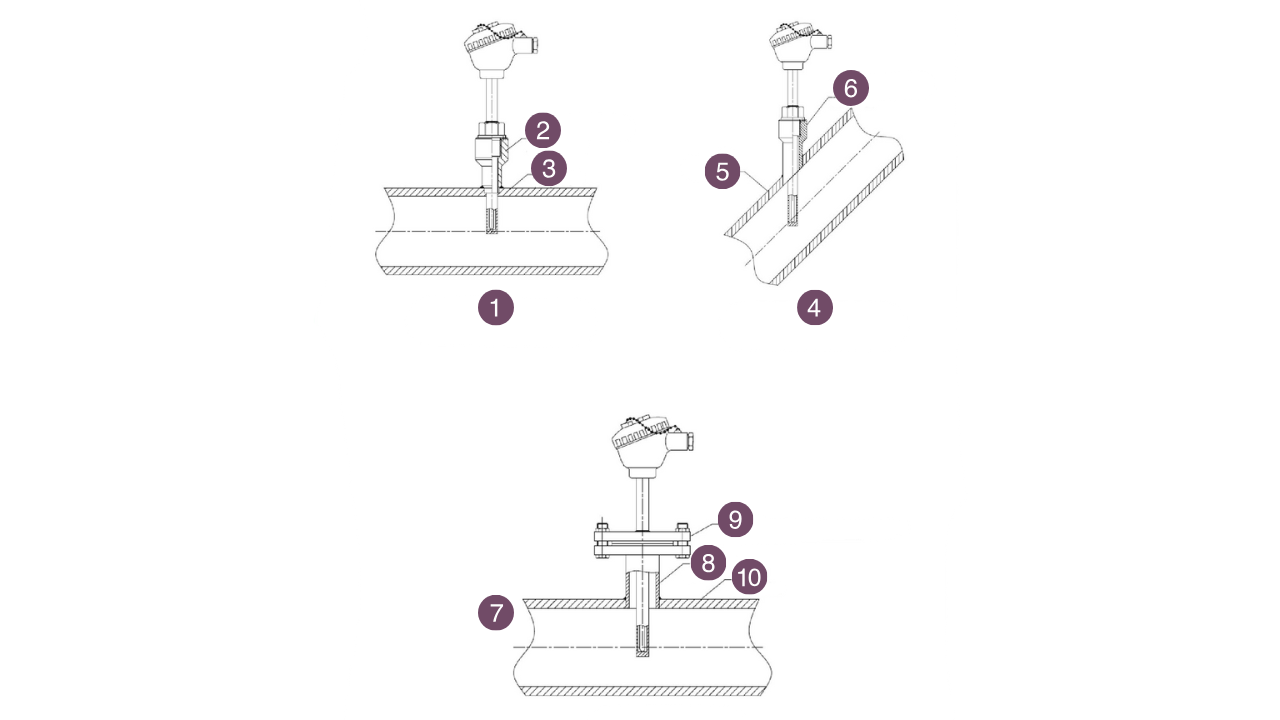

Installation form

- Vertical pipeline installation

- Straight connector

- Tube

- Inclined pipeline installation

- Tube

- Straight connector

- Flange installation

- Short tube

- Flange installation

- Tube

Straight connector

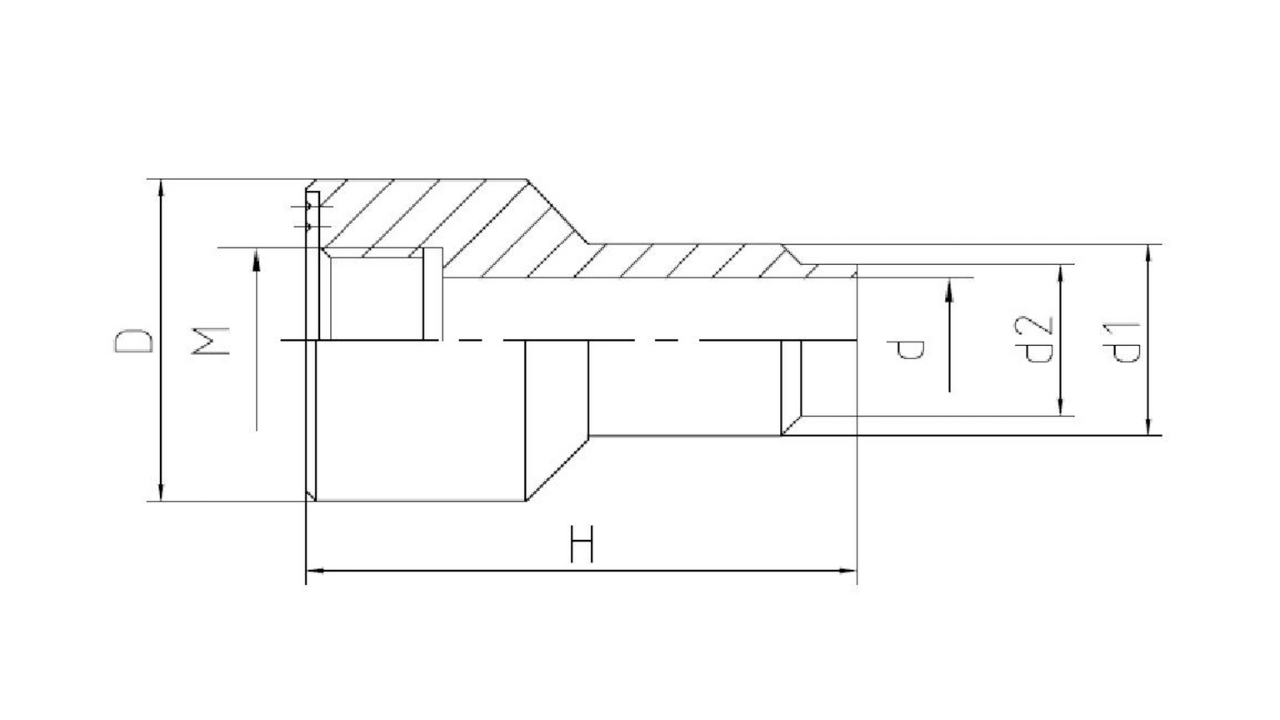

TH48 size

| Code | M | D | d | d1 | d2 | H |

|---|---|---|---|---|---|---|

| TH48A | M12x1.5 | Ф32 | Ф7 | Ф18 | Ф12 | 60, 120 |

| TH48B | M16x1.5 | Ф34 | Ф10 | Ф24 | Ф14 | 80 |

| TH48C | M20x1.5 | Ф39 | Ф10 | Ф26 | Ф14 | 60 |

| TH48D | M27x2 | Ф47 | Ф22 | Ф32 | Ф26 | 60 |

| TH48E | M33x2 | Ф55 | Ф22 | Ф36 | Ф26 | 120 |

| TH48F | NPT1/2 | Ф39 | Ф16 | Ф27 | Ф21 | 60, 120 |

| TH48G | NPT3/4 | Ф47 | Ф20 | Ф31 | Ф25 | |

| TH48H | NPT1 | Ф47 | Ф30 | Ф41 | Ф35 |

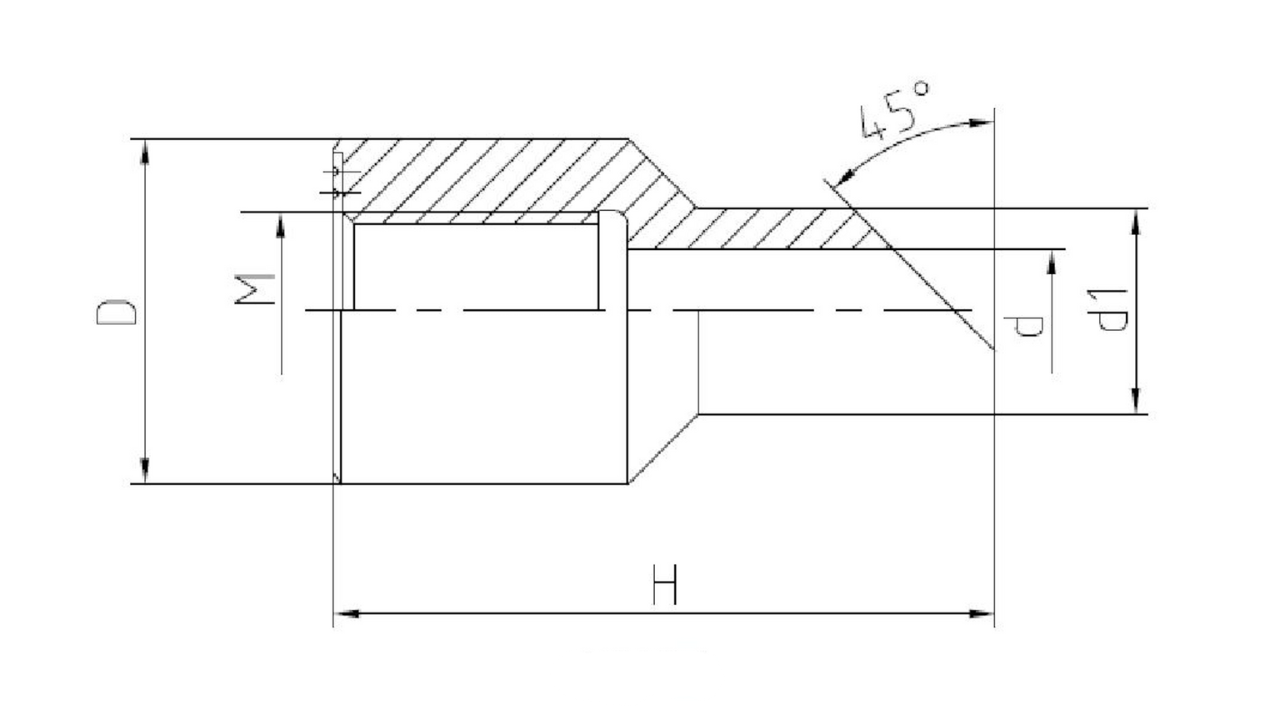

TH49 size

| Code | M | D | d | d1 | H |

|---|---|---|---|---|---|

| TH49A | M27x2 | Ф47 | Ф18 | Ф28 | 90 |

| TH49B | M33x2 | Ф55 | Ф24 | Ф36 | 150 |

| TH49C | NPT1/2 | Ф39 | Ф16 | Ф27 | 90 |

| TH49D | NPT3/4 | Ф47 | Ф20 | Ф31 | 90 |

| TH49E | NPT1 | Ф47 | Ф30 | Ф41 | 150 |