Explosion-Proof Thermocouple

Product Application

Usually used in conjunction with display instruments, recording instruments, electronic computers and so on. Direct measurement of various production processes (0 ~ 1300)°C range of liquid, steam and gas media and solid surface temperature.

Product Principle

According to the gap explosion-proof principle, explosion-proof thermocouples are designed with sufficient strength of the junction box and other components, all the parts that will produce sparks, arcs and dangerous temperatures are sealed in the junction box cavity. When an explosion occurs in the cavity, it can be quenched and cooled through the gap between the joint surfaces, so that the flame and temperature after the explosion can not be transmitted outside the cavity, thus providing explosion-proof.

Product Features

- Suitable for a wide range of explosion-proof environments.

- Spring compression type temperature sensing element, good vibration resistance.

- Large measuring range.

- High mechanical strength, good pressure resistance.

Technical Parameters

1. Executive Standard of the Product

- National standard GB/T30429, GB/T3836.

2. Room Temperature Insulation Resistance

The insulation resistance of the Explosion-Proof Thermocouple is ≥ 1000 MΩ between the electrode and the outer casing at an ambient temperature of (20 ± 15)°C, a relative humidity of not more than 80%, and a test voltage of (500 ± 50)V DC.

3. Temperature measurement range and tolerance

| Model | Graduation | Tolerance level | |||

|---|---|---|---|---|---|

| I | II | ||||

| Tolerance value | Temperature range | Tolerance value | Temperature measurement range | ||

| WRNK | K | -40 ~ +375 | ±1.5°C | -40 ~ +333 | ±2.5°C |

| 375 ~ 1000 | ±0.004|t| | 333 ~ 1200 | ±0.0075|t| | ||

| WRMK | N | -40 ~ +375 | ±1.5°C | -40 ~ +333 | ±2.5°C |

| 375 ~ 1000 | ±0.004|t| | 333 ~ 1200 | ±0.0075|t| | ||

| WREK | E | -40 ~ +375 | ±1.5°C | -40 ~ +333 | ±2.5°C |

| 375 ~ 800 | ±0.004|t| | 333 ~ 900 | ±0.0075|t| | ||

| WRFK | J | -40 ~ +375 | ±1.5°C | -40 ~ +333 | ±2.5°C |

| 375 ~ 750 | ±0.004|t| | 333 ~ 750 | ±0.0075|t| | ||

| WRCK | T | -40 ~ +125 | ±0.5°C | -40 ~ +133 | ±1.0°C |

| 125 ~ 350 | ±0.004|t| | 133 ~ 350 | ±0.0075|t| | ||

| WRPK | S | 0 ~ +1100 | ±1.0°C | 0 ~ 600 | ±1.5°C |

| 1100 ~ 1600 | ±[1+0.003(t-1100)] | 600 ~ 1600 | ±0.0025|t| | ||

| WRQK | R | 0 ~ +1100 | ±1.0°C | 0 ~ 600 | ±1.5°C |

| 1100 ~ 1600 | ±[1+0.003(t-1100)] | 600 ~ 1600 | ±0.0025|t| | ||

| WRRK | B | / | / | 600 ~ 1700 | ±0.0025|t| |

4. Explosion proof grouping form

| Prefix | Type of Protection | Equipment Group | Gas/Dust Grouping | Temperature group |

|---|---|---|---|---|

| Ex | db: Explosion-proof | II: Class II electrical equipment | A, B, C | T1~T6 |

| ia: Intrinsically safe | ||||

| tb: Dust type | III: Class III electrical equipment |

5.Maximum surface temperature grouping of Class Il electrical equipment

| Temperature grouping | Maximum surface temperature (°C) |

|---|---|

| T1 | ≤240 |

| T2 | ≤300 |

| T3 | ≤200 |

| T4 | ≤135 |

| T5 | ≤100 |

| T6 | ≤85 |

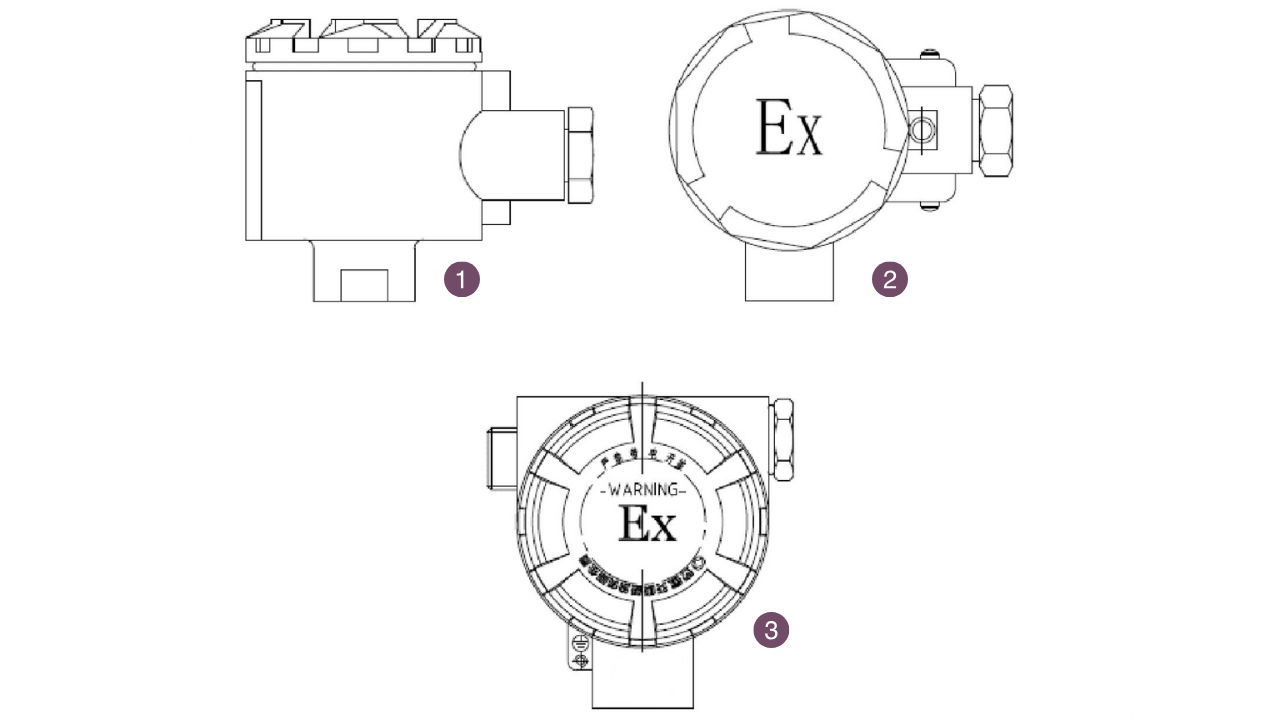

6. Terminal box form

Protection level: IP65, IP66, IP68

- A type

- B type

- C type

7. List of certification information

| Name | Maximum surface temperature (°C) | Certificate authority |

|---|---|---|

| Explosion proof thermocouple | Ex db IIC T4...T6 Gb / Ex tb IIIC T80°C...T130°C Db | NEPSI |

| Ex db IIB T4...T6 Gb, Ex tb IIIB T80°C...T130°C Db | NEPSI | |

| Intrinsic safety thermocouple | Ex db IIC T4...T6 Gb, Ex ia IIIC T135°C/T200°C Da | NEPSI |

Model Naming Method

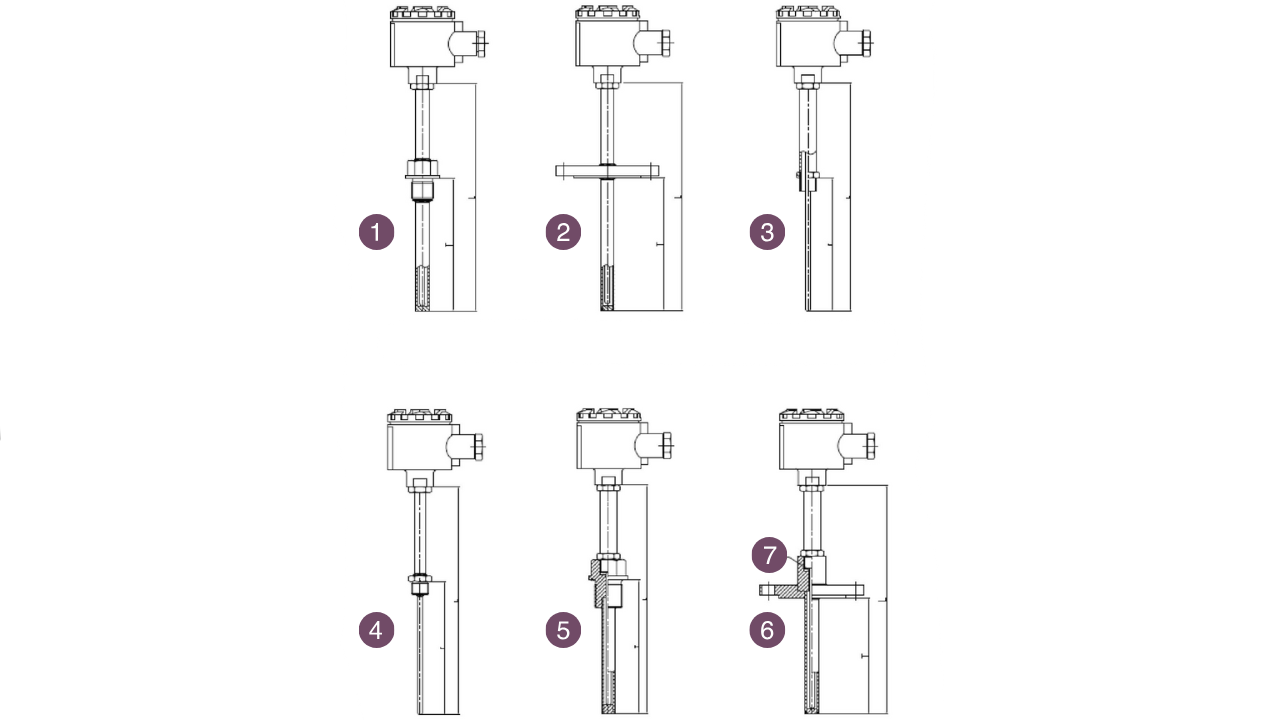

Structure diagram

- WRN-240/241

- WRN-440/441

- WRN-74

- WRN-84

- WRN-74-THO3H

- WRN-74-TH02B

- Isolation

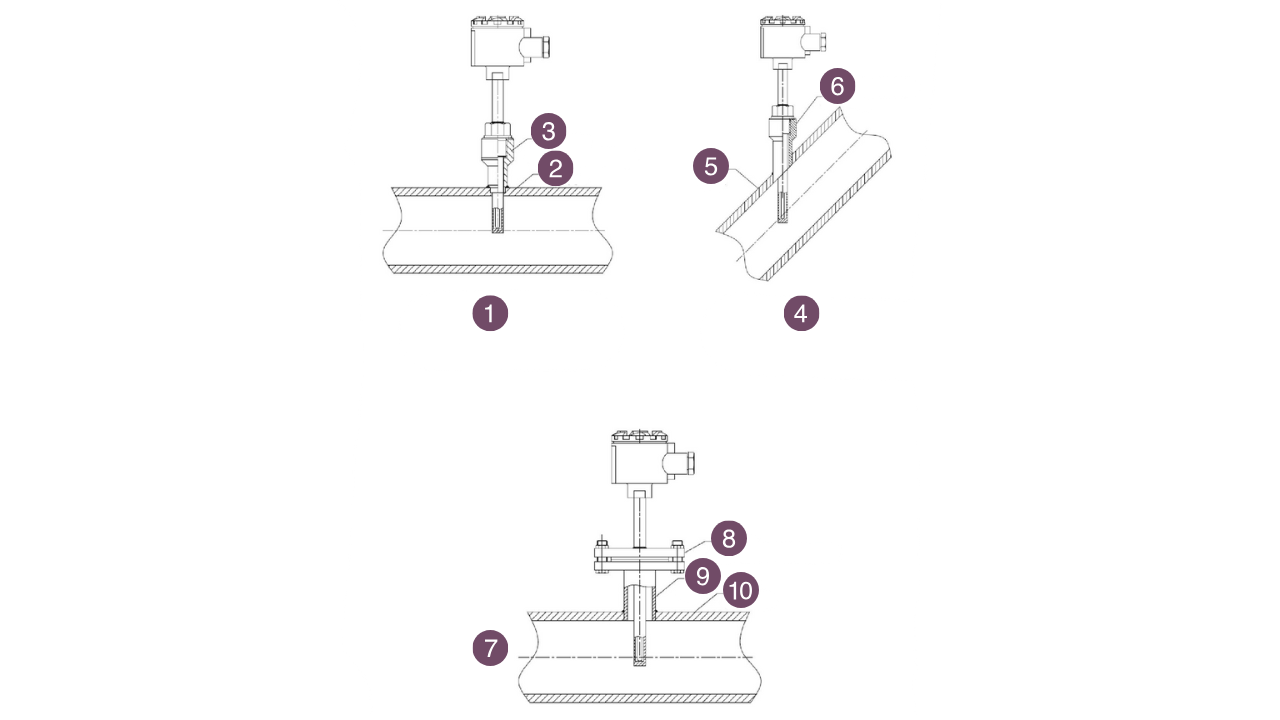

Installation form

- Vertical pipeline installation

- Tube

- Straight connector

- Inclined pipeline installation

- Tube

- Straight connector

- Flange installation

- Fitting Flanges

- Short tube

- Tube